⭐ The Complete Workflow: Scan, Design, and Make in Digital Dentistry

Digital dentistry has redefined how modern clinics operate, offering a streamlined and highly efficient workflow that enhances precision, reduces time, and significantly improves patient outcomes.

Today, the Scan–Design–Make workflow stands at the heart of digital dental practices, allowing clinicians to transition from diagnosis to final restorations with unmatched accuracy and speed.

This end-to-end digital ecosystem enables clinics to work smarter, faster, and with greater confidence — making digital dentistry not just an upgrade, but a complete transformation.

1. Scan — Capturing Accurate Digital Impressions

The digital workflow begins with high-precision scanning.

Intraoral scanners replace traditional impressions with a faster, cleaner, and more comfortable alternative.

Key benefits of digital scanning include:

-

Immediate 3D visualization

-

High accuracy with minimal errors

-

Enhanced patient comfort

-

Faster diagnosis and planning

-

Seamless integration with CAD/CAM systems

Digital scans serve as the foundation of every subsequent step — making accuracy at this stage essential.

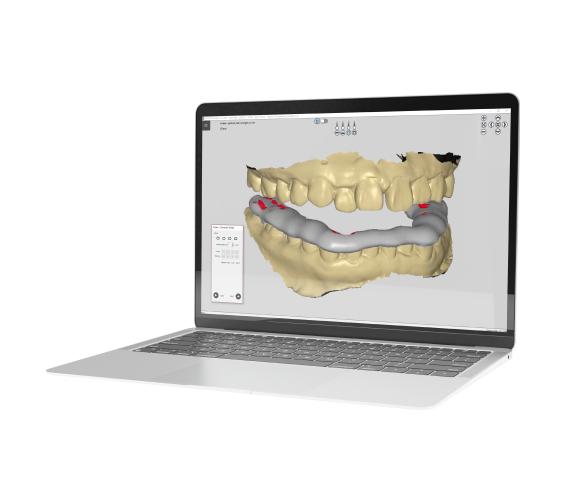

2. Design — Creating Precise CAD Restorations

After scanning, the data moves to advanced CAD software where clinicians or dental technicians design restorations with exceptional accuracy.

Digital design tools allow for:

-

Precise creation of crowns, bridges, veneers, and guides

-

Real-time adjustments

-

Improved anatomical accuracy

-

Enhanced functional and aesthetic results

-

Predictable treatment outcomes

The ability to visualize the final restoration before production ensures a more controlled workflow with fewer errors.

3. Make — In-House Production with 3D Printing & Milling

The final step is production — where the digital design becomes reality.

Modern clinics use 3D printers and milling units to fabricate restorations and clinical tools directly in-house.

Advantages include:

-

Same-day restorations

-

Reduced laboratory costs

-

Higher quality control

-

Faster turnaround time

-

Tailored solutions for every patient

From temporary crowns to surgical guides and permanent restorations, digital production dramatically improves workflow efficiency.

How the Digital Workflow Transforms Clinics

Adopting the Scan–Design–Make system brings transformative benefits:

-

Shorter appointments and less waiting time

-

Greater precision and consistent clinical results

-

Improved patient experience

-

Increased productivity and profitability

-

Seamless integration with digital imaging and planning tools

Clinics that embrace this workflow are better positioned to meet the demands of modern dentistry.

Conclusion

The Scan–Design–Make workflow represents a new era of digital dentistry — where accuracy, speed, and patient satisfaction come together in a fully integrated system.

At Glory, we deliver the advanced scanners, CAD/CAM tools, 3D printers, and milling systems that make this transformation possible.

Empowering clinics with complete digital workflows ensures better outcomes, smoother processes, and exceptional patient care.

Digital dentistry is no longer the future — it is the standard of excellence today.